Digital Solutions

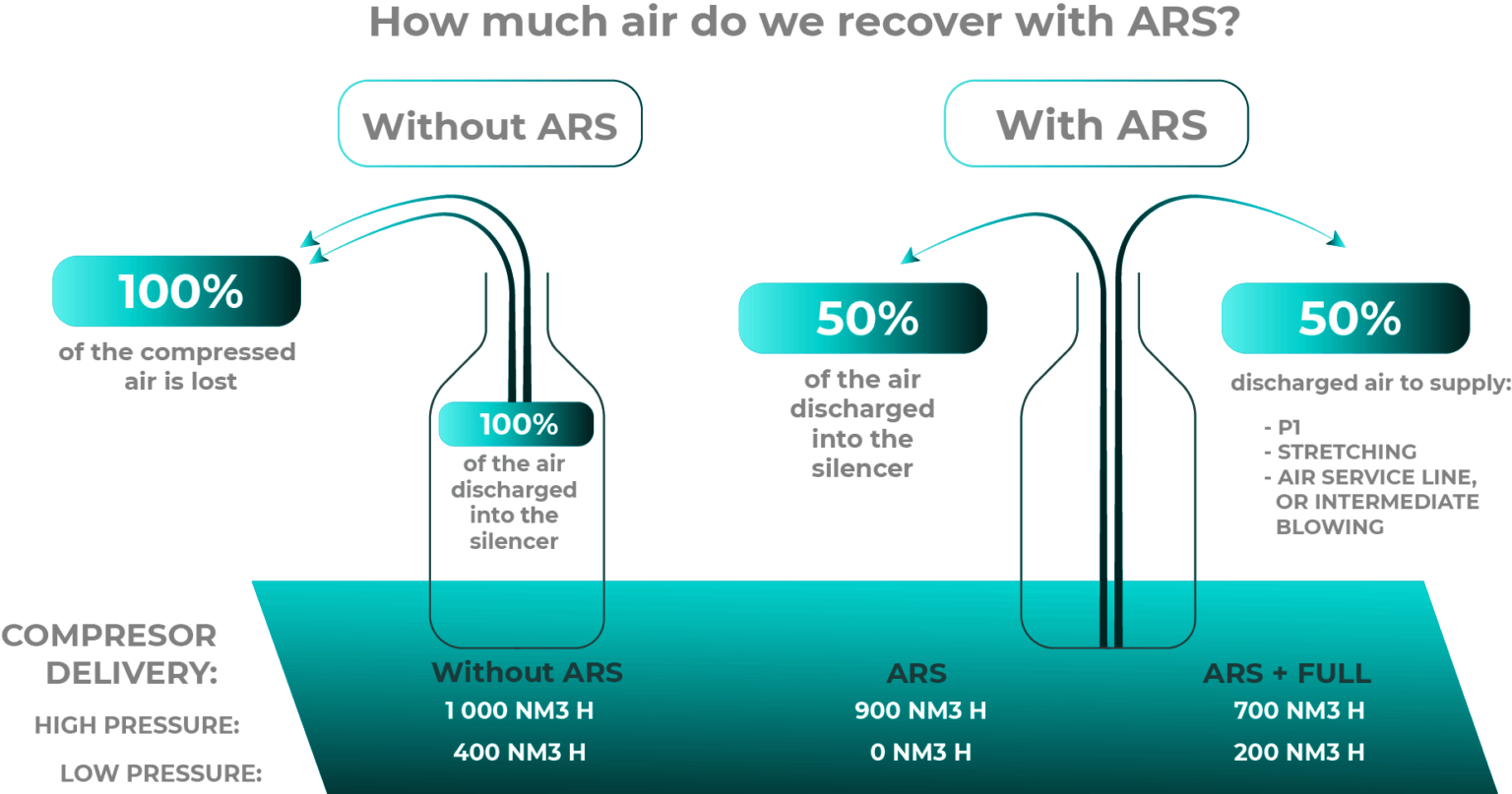

ARS

Up to 60% recovery of the discharged air, to supply the preblow step and service air inside the machine; the excess of recovered air is pushed to the utillity line of the plant

ARS + HP

Up to 30% net hp air savings, the recovered air supplies the preblow and intermediate blowing steps

Customer Spotlight

State-of-the-art recoverty system, up to 40% net hp air savings. The recovered air supplies the preblow and intermediate blowing steps, as well as the service air needs inside the wheel.

An ARS system saving 102 Nm3h HP air and 277 Nm3h LP air per hour, OVER 5000 hours a year, allows savings of 60.125kW/ h or 300.000 kW/ year.

On top the 30.000 EUR/year financial savings (with 1 kW = 0.10 EUR), the energy-savings project TOEO allows significant carbonated footprint savings for the plant.

The equivalent CO2 emission represents: